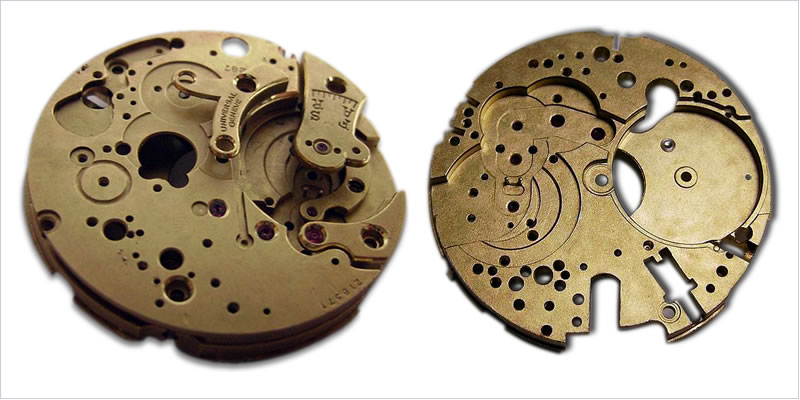

Here is the description of the restoration of a Universal Tricompax watch with a stainless steel pressure case.The object had undergone heavy water seepage that caused, as shown in the pictures, the steel parts of the movement getting rusted and, in a longer time, the corrosion of the brass of which are made up the plate and the bridges.

Come prima cosa abbiamo deciso di intervenire su quest’ultimi (ponti e platina), allo scopo abbiamo provveduto a smontarFirst of all we decided to treat the bridges and the plate. In order to do that, all the steel units of the movement have been dismantled. The first process consists of removing all spots and corrosions by sandblasting (abrasive blasting)./First of all, each steel unit of the movement has been dismantled in order to proceed on the treatment of the bridges and the plate, which consists of removing all spots and corrosions by sandblasting (abrasive blasting).

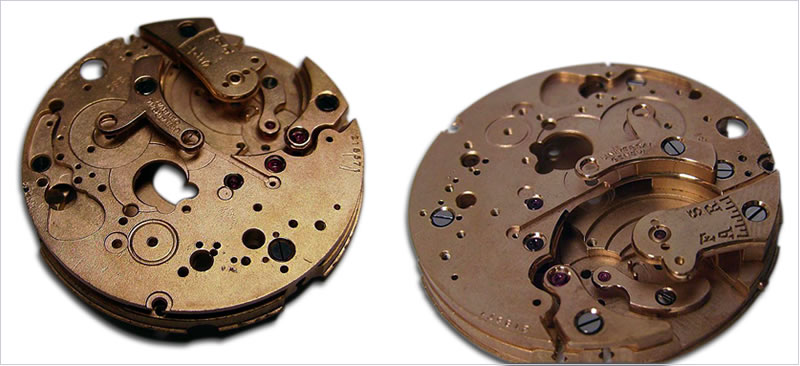

The surface obtained by means of sandblasting is shaped simply smooth, while in that movement the bridges’ perimetric edges and the flares of the rubies’ sets were originally bright, so we polished them up.Hereafter has been made the gold plating (electroplating) of all the brass elements, resulted without protection after the sandblasting, to avoid their oxidation.

Then has followed the removal of the rust and the steel welding anywhere the loss of material was excessive and the high-end finishing of bevelling of every single unit of the chronographic parts.In order to complete the restoration treatment the heads of the screws have been polished up and finally brought back to their flatness.